Home / About us

We manufacture sheet metal pressed/stamped components, switchgear assemblies & control panels as per the customer's requirements. Our main focus is on value engineering and cost reduction in all our activities, including sheet metal components & assemblies - hence offering the customer an advantage in the market. We've been able to design tooling and processes that have reduced material wastage as much 35% and price reduction of 40% in some components.

The Panel shop manufactures Switchboards (PCCs/MCCs) including complete assembly and testing. The quality of wiring from boards delivered by Press Metal Industries is of the same level as that of our Principal’s.

Our assembly shop has been awarded 'Green Channel' and for the last three years, assemblies made by us are self-certified (and not inspected by the customer) and quality score has been 100/100 so far.

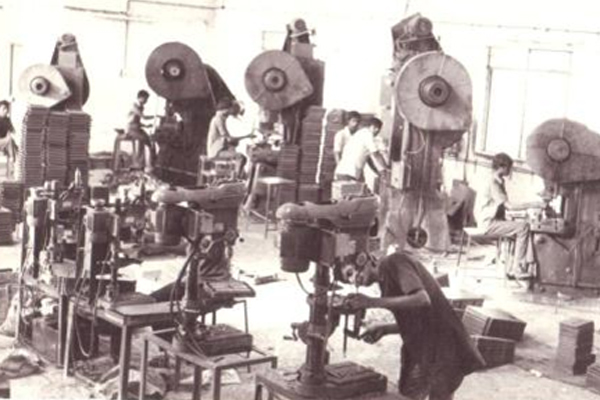

PMI Satpur in 1981 with a modest Press Shop & Tool Room started for Crompton Greaves, Nasik

B. Tech - Mechanical Engineering from I.I.T. Powai.

9 years work-experience in Larsen & Toubro Limited, Powai Works, MUMBAI in Quality Control, Tool Design & Manufacture & Vendor Development.

Started his own manufacturing of sheet metal components & electromechanical assemblies in 1981 and has been successfully running the business with quality and customer services and cost reduction as the guiding principles. The total turnover of all the manufacturing units owned by Mr. Mundra was Rs. 24 Crores in the year 2008-2009

M.S. in Robotics & B.E. Mechanical.

Technical Support, Engineering Liaison, Product Development, Manufacturing Engineer, Reliability Testing & Systems Engineer were the roles played during his 4 year tenure in the USA working for a Fortune 16 firm in their Robotics Division.

Now joined family business since June 2008 – got 3 new projects from 3 reputed customers – production established and running smoothly.

PGDM (MARKETING) & B.COM

Product Management, Business Development , Market Management , Market Preparation , Strategy & Execution , Program Management , Forecasting ,Brand Management are roles played in his 14 years of career with leading private bank sector .

Now joined family business since March 2016

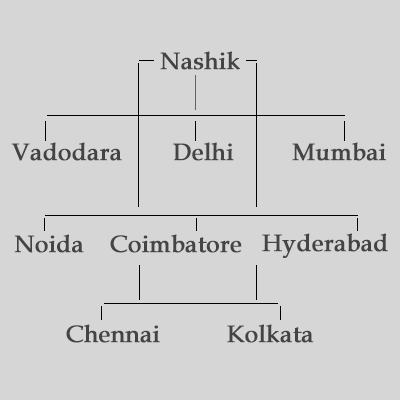

| Unit | Location | Major Customers | Activity |

|---|---|---|---|

| PRESS METAL INDUSTRIES P.M.I. www.pmiglobal.co.in | E- 47 Satpur | Schneider Electric CG Lucy Lucy Electric L&T | Design Press Shop Tool Room Assembly Fabrication |

| NASIK METALDUST PVT. LTD. N.M.D. www.nasikmetaldust.co.in | 65, Satpur MIDC | Schneider Electric CG Lucy Efecec TF4GLOBAL GM L&T Legrand LK |

Design Press Shop Relay Assembly DB Assembly Powder Coating |

| NASIK METALDUST PVT. LTD. N.M.D. www.nasikmetaldust.co.in | D-55, Ambad MIDC |

Schneider Electric CG Lucy Efecec TF4GLOBAL GM L&T Legrand LK |

Design Press Shop Relay Assembly DB Assembly Powder Coating |

| Equipment | Target Year | Target Quarter |

|---|---|---|

| Optical Measurement System | 2014-15 | Q2 |

| Web Based ERP | 2015-16 | Q4 |

| Robotic Welding for small assemblies | 2014-15 | Q3 |

| CNC Turret or Laser | 2015-16 | Q2 |

| Fully Automatic Coating System | 2016-17 | Q4 |

Q3, 2015-16

Land for industrial use

Q3, 2016-17

Building - 50,000 sq ft

Q4, 2017-18

Additional – 50,000 sq ft

Press Metal is divided into three departments: Press Shop, Panel Shop & Assembly Shop. The list of machinery used in the three departments are as follows:

We have 17 Mechanical Power Presses ranging from 25 Tons to 150 Tons. The tool room is equipped with a lathe, milling machine, two surface grinders & a shaper to help quick turnaround of new tools. 5 drilling/tapping machines to support second operations on components. The QA department is armed with modern equipment to ensure that the components are produced to specifications.

The Panel Shop is equipped to design and manufacture the copper/aluminium links required in the Control Panels. The list of equipment for this activity is: two specialized link bending machines, three mechanical power presses & two hydraulic presses for punching and cutting and a conveyor type heater for sleeving. Use of pneumatic hand tools is encouraged in the panel assembly process so as to reduce the effort required and also guarantee strength of bolted joints.

The assembly shop is equipped with an array of CO2 welding machines with appropriate fixtures to produce accurate welded assemblies; two spin riveting machines & ancillary pneumatic tools.

"We are building up our core competencies to be a complete sheet metal solutions expert, so that we can offer customers a one stop shop for all their sheet metal needs"...

ETP (Effluent Treatment Plant) for appropriate disposal of chemicals and sludge conforming with MPCB

norms.

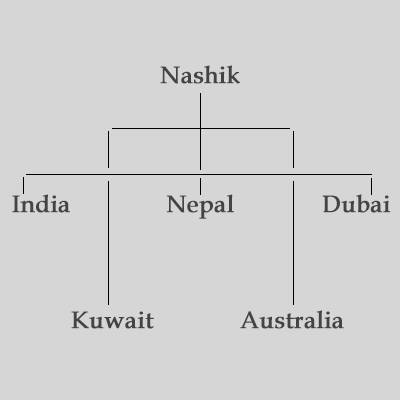

Located on the Mumbai-Agra National Highway (NH-3)

Situated strategically at 175 km distance from Mumbai, Pune and Aurangabad equally

Excellent road connectivity making dispatches easy through out the country

Nasik being an electrical hub, sourcing for parts is vey easy

JNPT (Nhava Sheva) Port is at 197 kms making international dispatches convenient